|

The Productive

Process The Productive

Process

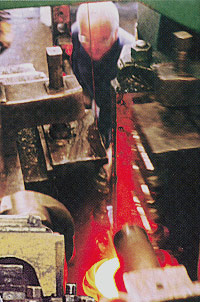

The

excellence in the design of our forgings is complemented by a

strict quality control in every step of the production

process. It begins with the reception of steel with is

controlled, classified, and stored according to the heat codes

of the steel mills. Steel later goes to the cutting sector,

where with the latest shearing equipment it is cut, achieving

close tolerances in weight which satisfy the requirements of

modern forging processes.

The parts are manufactured in vertical

forging up to 3000 tons and horizontal upsetters from 2 to 8

inches of capacity, which are complemented with ancilliary

equipment such as trimming and coining presses, forging rolls,

etc. The forging lines are equipped with total or bar end

induction heating equipment with automatic temperature control

of the forgings during the process. |

|

| |

|

| |